High-Quality Surfactants for Global Markets - Trusted Manufacturer

PRODUCT PARAMETERS

Description

Overview of Nonionic Surfactant

Nonionic surfactants are surface-active agents that do not ionize in aqueous solutions. They are widely used in various industries, including detergents, cosmetics, and pharmaceuticals, due to their excellent solubilizing, emulsifying, and wetting properties. These surfactants are derived from alcohols, acids, or amines and are known for their versatility and compatibility with other surfactants.

Features of Nonionic Surfactant

Non-Ionic Nature: Do not form ions in water, making them less sensitive to hard water and electrolytes.

Versatility: Compatible with both anionic and cationic surfactants, allowing for broad formulation flexibility.

Solubilization: Excellent at solubilizing oils and other hydrophobic substances.

Emulsification: Effective in creating stable emulsions, which is crucial for many cosmetic and pharmaceutical formulations.

Wetting Ability: Enhances the wetting of surfaces, improving cleaning efficiency.

Low Foaming: Generally produce less foam compared to other types of surfactants, which can be advantageous in certain applications like industrial cleaning.

Temperature Stability: Maintain effectiveness over a wide range of temperatures, making them suitable for high-temperature processes.

Environmental Friendliness: Some nonionic surfactants are biodegradable, contributing to more environmentally friendly products.

(Anionic Cationic Nonionic Polyacrylamide for Drilling Fluid Chemicals)

Specifications of Anionic Cationic Nonionic Polyacrylamide for Drilling Fluid Chemicals

Here are the specs for Anionic, Cationic, and Nonionic Polyacrylamide made use of in exploration liquids:

Polyacrylamide (PAM) is a crucial chemical for drilling muds. It can be found in three major kinds: Anionic, Cationic, and Nonionic. Each kind offers certain objectives underground. Understanding their specs aids select the right one.

Anionic PAM carries a negative charge. It functions well in fresh water or low-salt muds. Its primary task is controlling clay and drilled solids. It protects against clay particles from swelling. It likewise assists glob little solids with each other for simpler removal. This improves mud top quality. Search for high molecular weight anionic PAM. High molecular weight provides much better thickness and fluid loss control. It normally comes as a white powder or granules. It dissolves fairly quickly in water.

Cationic PAM lugs a positive charge. It tackles sticky, water-sensitive shales successfully. It binds highly to negatively billed clay surfaces. This stops shale hydration and disintegration. It maintains the borehole wall surface. It additionally assists control fluid loss. Cationic PAM commonly has a tool molecular weight. It provides great shale inhibition. It comes as a white or slightly yellow powder. Dissolution could require more care than anionic types.

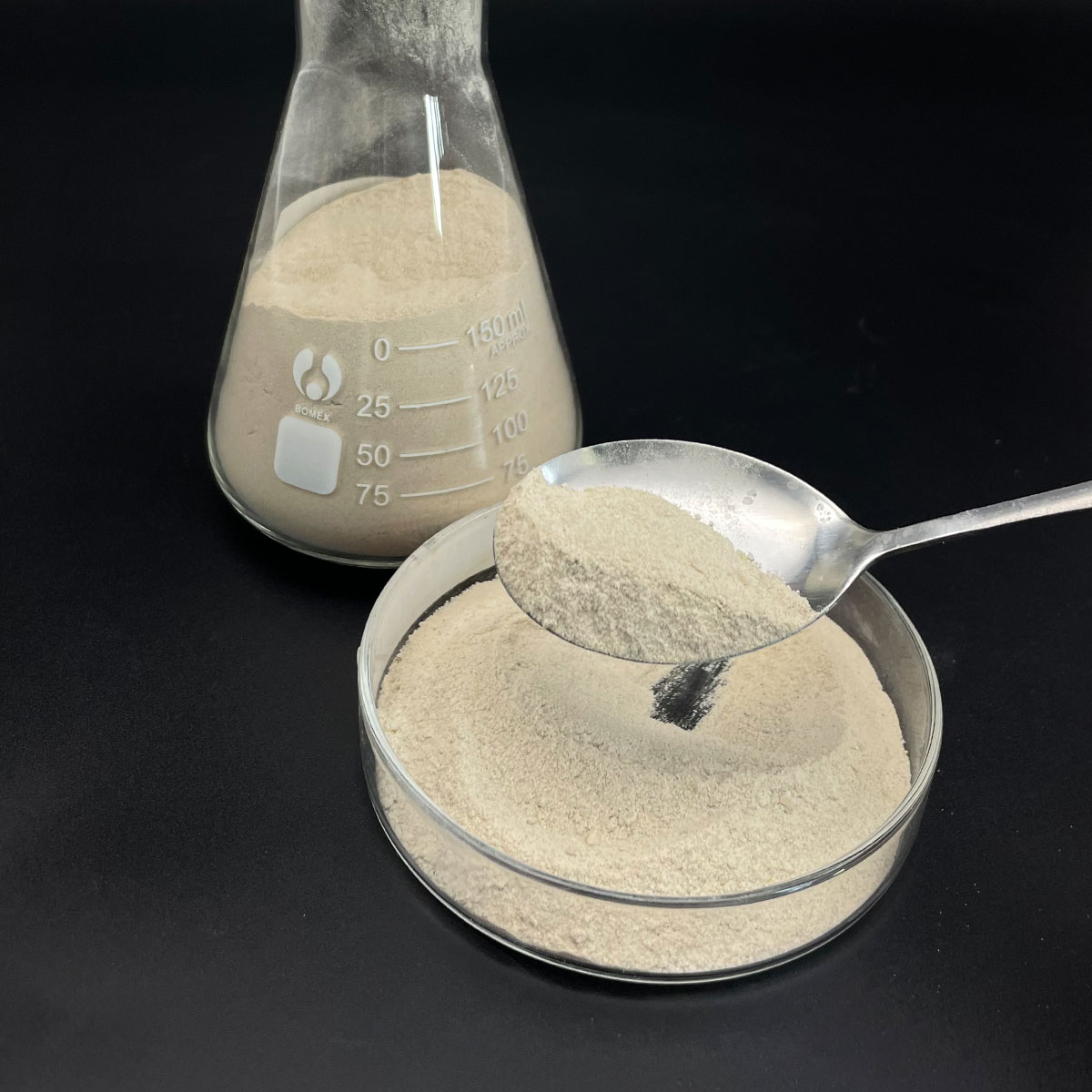

Nonionic PAM has on the house. It works in a vast array of water chemistries. It takes care of high salinity or difficult water problems well. Nonionic PAM is a flexible flocculant and liquid loss reducer. It aids thicken the mud slightly. It boosts suspension of cuttings. Nonionic PAM normally has very high molecular weight. This offers solid flocculation power. It is normally a white powder. Dissolution can take longer. Mild blending aids prevent lumps.

All PAM kinds share some typical specifications. Solid content is usually above 90%. Recurring monomer levels are maintained extremely low, below 0.05%, for safety. Particle dimension is regulated for regular dissolving. pH is typically near neutral. Insolubles are very little. Correct storage space is completely dry and awesome. Deal with powders very carefully to avoid dirt. Always add PAM gradually to water with excellent agitation. Pre-mixing a slurry often works finest. Comply with the distributor’s recommended dose. Too much can make the mud as well thick.

(Anionic Cationic Nonionic Polyacrylamide for Drilling Fluid Chemicals)

Applications of Anionic Cationic Nonionic Polyacrylamide for Drilling Fluid Chemicals

Anionic cationic nonionic polyacrylamide are essential polymers made use of in exploration fluids. They fix numerous usual drilling troubles. Exploration liquid have to work well below ground. It lugs rock cuttings to the surface. It cools down and oils the drill bit. It likewise holds the wellbore walls stable. Water-based liquids encounter difficulties. Water can make clay formations swell. Shale layers can break apart. Solids can develop way too much. Fluid can leak into the formation. Polyacrylamides aid handle these problems.

Anionic PAM is very good for shale stabilization. Shale takes in water easily. This causes swelling and collapsing. Anionic PAM coats shale surface areas. It produces a safety movie. This film stops water from getting in the shale. The wellbore stays solid and intact. Hole collapse risk drops. Anionic PAM likewise helps manage fluid loss. It secures tiny pores in rock formations. Much less fluid leaks away. Fluid properties stay constant.

Cationic PAM tackles clay diffusion troubles. Clay bits break down in water. They make the mud thick and sticky. Cationic PAM makes clay fragments clump with each other. This is called flocculation. The bigger clumps resolve out much faster. Mud stays thinner. Pumping calls for less power. Cationic PAM additionally enhances wellbore cleansing. It maintains cuttings relocating upwards.

Nonionic PAM is very versatile. It works well in different water top qualities. It doesn’t react strongly with salts. Nonionic PAM generally manages viscosity. It makes the boring liquid thicker. Thicker liquid lugs cuttings better. It additionally assists put on hold solids. Solids do not sink swiftly. Nonionic PAM help fluid loss control as well. It forms a tough filter cake on the borehole wall surface.

Using the right polyacrylamide type boosts drilling efficiency. It minimizes downtime. It lowers costs. Operators get better opening conditions. They attain faster infiltration rates. Fluid buildings stay convenient.

Company Introduction

Welcome to Robocup, a premier global supplier of high-quality surfactants. Our extensive range includes anionic, cationic, nonionic, and amphoteric surfactants, catering to industries such as personal care, textiles, cleaning, and industrial applications. With advanced manufacturing facilities and rigorous quality control, we ensure that our products meet the highest international standards. We pride ourselves on our commitment to innovation, sustainability, and customer satisfaction. Our dedicated team provides tailored solutions to meet your specific needs. Partner with us for reliable, high-performance surfactants that drive your business forward. Explore our offerings and discover the difference today.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Anionic Cationic Nonionic Polyacrylamide for Drilling Fluid Chemicals

Here are 5 FAQs about Anionic, Cationic, Nonionic Polyacrylamide for Drilling Fluids:

What does polyacrylamide do in drilling fluids? Polyacrylamide (PAM) helps control the drilling mud. It makes the mud thicker. Thicker mud carries rock cuttings better. It also creates a thin, tough filter cake on the wellbore wall. This filter cake stops drilling fluid loss. It stabilizes the hole. PAM reduces friction too. Less friction means easier drilling.

What is the difference between anionic, cationic, and nonionic PAM? The difference is their electrical charge. Anionic PAM has a negative charge. Cationic PAM has a positive charge. Nonionic PAM has no charge. This charge difference matters. It affects how each type interacts with clay particles in the mud. It changes how they thicken the mud.

When should I use each type of PAM? Choose based on the mud system and formation. Anionic PAM works best in freshwater muds. It is good for flocculating clay. Cationic PAM works well in muds needing strong clay inhibition. It helps prevent clay swelling. Nonionic PAM is stable in salty water or high hardness water. Use it when salts or calcium are present.

How much PAM should I add? Start with a low dosage. Typical ranges are 0.05% to 0.3% by weight of the mud. Add it slowly. Mix it thoroughly. Observe the mud properties. Check the viscosity and fluid loss. Adjust the amount as needed. Too much can make the mud too thick. Too little might not control fluid loss enough.

Is PAM safe to handle? Handle PAM carefully. Wear gloves and eye protection. Avoid breathing the dust. Keep it away from water sources before mixing. Once dissolved in the mud, it is generally safe. Follow the supplier’s safety data sheet exactly. Store it in a cool, dry place.

(Anionic Cationic Nonionic Polyacrylamide for Drilling Fluid Chemicals)

REQUEST A QUOTE

RELATED PRODUCTS

High-Quality S-80 Smo Span 80 Sorbitan Oleate Nonionic Surfactant for Global Distribution

Aphid Killing Surfactant Nonionic for Silicone Adjuvant Harmless Botanical Insecticide Hemiptera Pest Control

Agricultural Nonionic Silicone Fluid Polydimethylsiloxane Surfactants

Silway 240 Nonionic Organic Silicone Oil Herbicide Penetrating Agent with Excellent Compatible Ability Silicone Adjuvant

Hot Big Nonionic Surfactant Polyethylene Glycol/Peg 400