High-Quality Surfactants for Global Markets - Trusted Manufacturer

Here’s a revised title and the blog web content:

(how to make calcium surfactant)

Title: Crafting Calcium Surfactant: The Scientific Research Behind the Suds

Blog site Material:

Ever heard of calcium surfactant? Most likely not. It seems like something from a modern lab, perhaps even a science fiction. But presume what? This special chemical plays a larger function in our globe than you might imagine. We’re diving deep right into what it is, why it matters, exactly how it’s made, where it’s utilized, and answering your burning questions. Prepare for a journey into the interesting world of specialized chemistry.

1. What Exactly Is Calcium Surfactant?

Okay, let’s break it down. A surfactant is essentially a particle that imitates a peacemaker. It minimizes tension between things that usually don’t blend well. Think oil and water. Ever see them divide? A surfactant assists them blend. It has 2 parts: one that enjoys water (hydrophilic head) and one that likes oils and fats (hydrophobic tail). This structure lets it connect the void in between different materials.

Currently, add calcium. Calcium surfactant is a particular type where the favorably charged component of the surfactant particle is calcium ions (Ca ² ⁺). Unlike typical surfactants like salt lauryl sulfate (assume soap), which have sodium ions, calcium surfactants have calcium. This little adjustment makes a huge distinction. Calcium surfactants are often harder, less water-soluble, and act in different ways in remedies. They’re less usual in everyday cleaning items since they can form residue with difficult water. However they shine in certain commercial applications where their special homes are required.

2. Why Bother Making Calcium Surfactant?

If routine surfactants function great for cleaning meals, why produce a calcium version? Excellent question. The response depends on its unique qualities. Calcium surfactants are recognized for being extremely steady, particularly in extreme conditions. They can handle heats and tough chemicals much better than many other surfactants. This makes them unbelievably resilient.

They also have a solid affinity for certain minerals and surface areas. This implies they stick well and engage incredibly where required. Because they are less soluble, they can develop steady films or obstacles. This is crucial for points like lubrication or producing protective finishings. In some chemical procedures, calcium ions are necessary or advantageous for the reaction itself. Using a calcium surfactant provides those ions right where the activity is taking place. So, while they might not be your go-to for washing, they are superstars in particular niche locations demanding toughness and specific interactions.

3. Just how Do You Actually Make Calcium Surfactant?

Making calcium surfactant isn’t something you attempt in your kitchen sink. It requires appropriate lab devices, safety and security gear, and chemical expertise. Below’s a basic concept of the process. Keep in mind, certain recipes differ depending on the exact surfactant kind.

First, you begin with a forerunner. This is typically a fatty acid, like stearic acid or palmitic acid. In some cases, it’s an organic acid by-product. You react this fat with a base. Sodium hydroxide (lye) is an usual option. This reaction generates the sodium salt of the fatty acid– essentially, a classic soap molecule. This is your surfactant anion.

Next comes the crucial action: ion exchange. You take your salt surfactant service and include a source of calcium ions. Calcium chloride (CaCl two) is commonly utilized for this. When you mix them, a chemical swap takes place. The calcium ions (Ca TWO ⁺) reject the sodium ions (Na ⁺) from the surfactant particles. Why? Calcium ions have a double positive cost (2+), while salt has a single (1+). Calcium binds a lot more strongly to the negatively billed surfactant head.

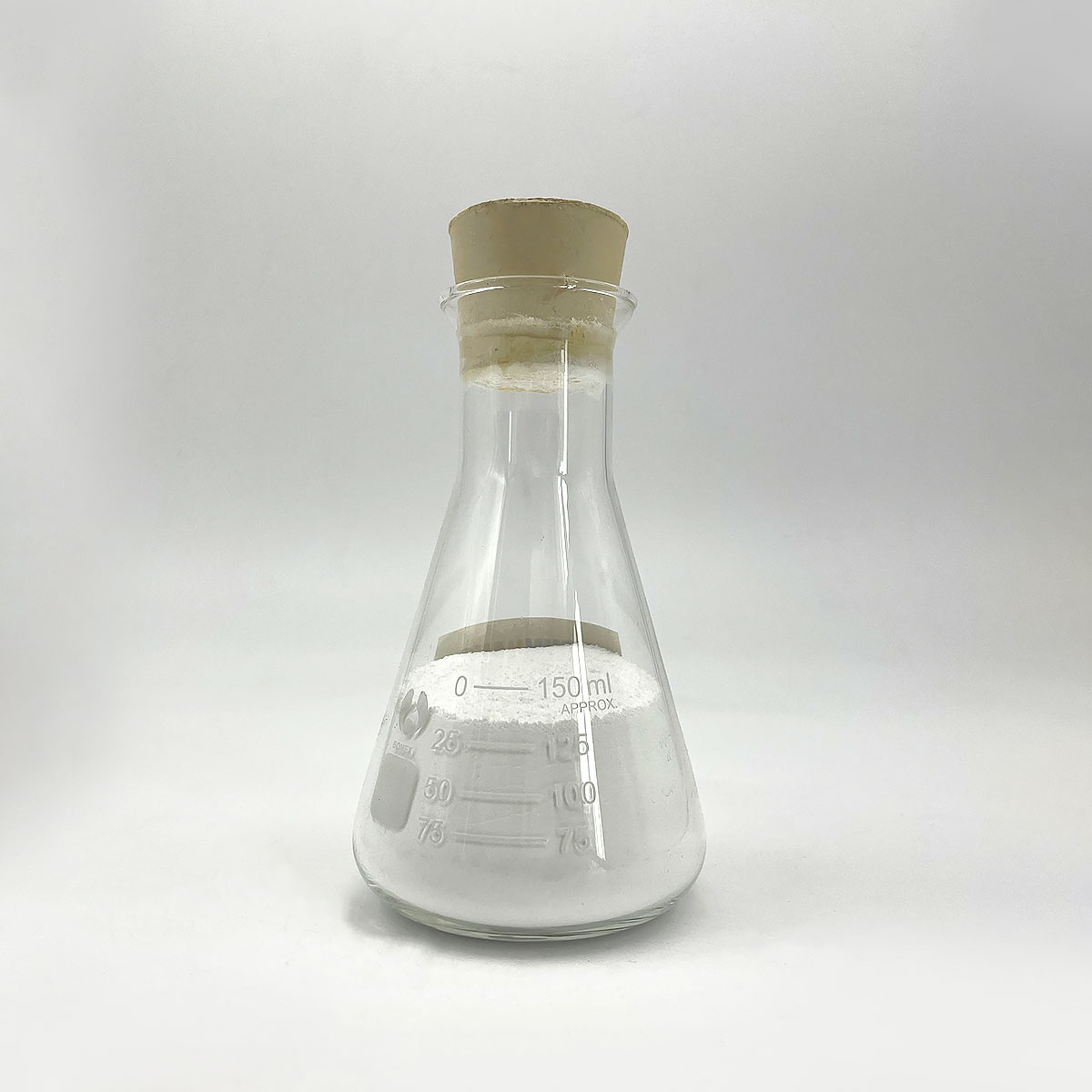

The result? Calcium surfactant precipitates out. It develops a strong or a thick paste due to the fact that calcium surfactants are much less soluble in water than their sodium cousins. You after that require to separate this solid product. Filtration is the normal technique. After filtering, you clean the strong to get rid of remaining salts or pollutants. Lastly, you dry it. This could suggest air-drying or utilizing an oven at low warm. The end item is your calcium surfactant, ready for its customized work.

4. Where Do We Use Calcium Surfactant Applications?

Calcium surfactants discover their particular niche in commercial and technological setups. Their unique residential properties make them useful for certain tasks.

Lubrication is a major location. Calcium surfactants are crucial elements in grease solutions. Oil isn’t just thick oil; it needs thickeners. Calcium soaps, particularly calcium stearate, function as outstanding thickeners. They hold the oil in place, producing a steady lube that stays put on equipment components, resisting water wash-off and high stress.

They play an essential role in polymer production, particularly for PVC (polyvinyl chloride). Calcium stearate works as a lube throughout the PVC manufacturing process. It assists the PVC bits circulation smoothly inside the handling devices. It likewise serves as a stabilizer, safeguarding the PVC from heat damage during manufacturing.

Plastics and rubber markets rely on calcium stearate also. It avoids sheets of plastic or rubber from sticking throughout storage space and handling. Think of it as an anti-blocking agent. It likewise helps launch molded components from their mold and mildews conveniently.

In building and construction, calcium stearate is utilized in concrete formulations. It serves as a waterproofing representative. It pushes back water, making concrete a lot more resistant to dampness damages. You could likewise discover it in some paints and coverings, helping in diffusion and circulation.

Cosmetics and personal treatment in some cases make use of very particular calcium surfactants, though less generally. They might be found in certain lotions or creams where their stability or certain feeling is wanted. However, salt or various other surfactants are much more normal for day-to-day cleansing.

5. Calcium Surfactant: Your Frequently Asked Questions Addressed

Allow’s deal with some typical questions regarding this one-of-a-kind product.

Is calcium surfactant the like soap residue? Type of, but not specifically. Soap residue is that unpleasant white film in your bath tub. It creates when routine soap (like salt stearate) responds with calcium or magnesium ions present in difficult water. The outcome is insoluble calcium stearate or magnesium stearate– basically, a sort of calcium surfactant. So, calcium surfactant is the chemical that comprises soap scum. But commercially made calcium surfactant is created intentionally for its useful buildings, not as an unwanted byproduct.

Can I make calcium surfactant in the house quickly? We strongly discourage it. The process involves taking care of possibly corrosive chemicals like lye (salt hydroxide) and calcium chloride. It calls for accurate dimensions, controlled conditions, and appropriate safety and security equipment (gloves, safety glasses, ventilation). Making it safely and appropriately is a work for trained experts in a lab or manufacturing facility setup. Stick to purchasing commercial items if you require them.

Is calcium surfactant toxic? Usually, calcium surfactants like calcium stearate are considered low in toxicity. They are typically utilized in food call applications (like in PVC pipelines or food packaging movies) and cosmetics. However, like any chemical, correct handling is crucial. Avoid inhalation of dirt and long term skin contact. Always inspect the Security Data Sheet (SDS) for the details product you are making use of for comprehensive safety and security info.

Why not make use of less expensive surfactants? Cost is a variable, yes. Sodium-based surfactants are commonly more affordable and quicker available. However occasionally, you require the particular performance that only calcium can provide. Its stability, thickening power, lubing ability, and water resistance in specific applications make it irreplaceable. For oils, PVC stabilization, and concrete waterproofing, calcium surfactants are typically the very best device for the job, justifying their use.

(how to make calcium surfactant)

What’s the difference in between calcium stearate and calcium surfactant? Calcium stearate is a specific kind of calcium surfactant. It’s made from stearic acid. Calcium surfactant is a wider group. It includes any kind of surfactant particle where the counterion is calcium. This can be based upon stearic acid, palmitic acid, oleic acid, or other fats. So, all calcium stearate is calcium surfactant, however not all calcium surfactants are calcium stearate. Various fatty acids give slightly different homes.