High-Quality Surfactants for Global Markets - Trusted Manufacturer

PRODUCT PARAMETERS

Description

Overview of Cationic Surfactant

Cationic surfactants are surface-active agents with a positively charged hydrophilic head. These surfactants are widely used in various industries, including personal care, textiles, and industrial cleaning. They are known for their antimicrobial properties, making them effective in disinfectants and fabric softeners. Their unique charge allows them to interact strongly with negatively charged surfaces, enhancing their effectiveness in specific applications.

Features of Cationic Surfactant

Positively Charged Head: The cationic nature of these surfactants makes them particularly effective in interacting with negatively charged surfaces.

Antimicrobial Properties: Effective against a wide range of microorganisms, making them ideal for use in disinfectants and sanitizers.

Fabric Softening: Commonly used in fabric softeners due to their ability to provide a soft feel and reduce static cling.

Emulsifying Ability: Can stabilize emulsions, which is useful in cosmetic and personal care products.

Foaming Characteristics: Produces stable foam, beneficial in cleaning products.

Solubility: Generally soluble in water and organic solvents, facilitating their use in various formulations.

Compatibility: Often compatible with other types of surfactants, allowing for versatile formulations.

(Asphalt Mixture Cationic Bitumen Emulsifiers for Cationic Bitumen Emulsion)

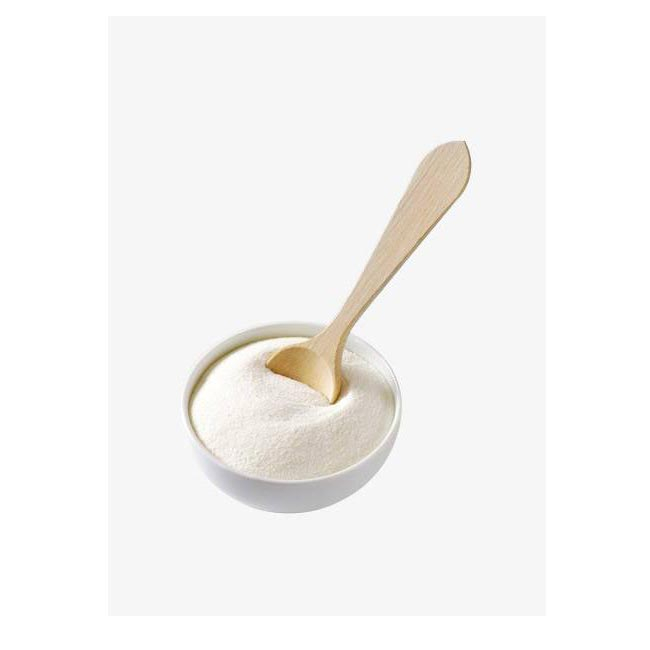

Specifications of Asphalt Mixture Cationic Bitumen Emulsifiers for Cationic Bitumen Emulsion

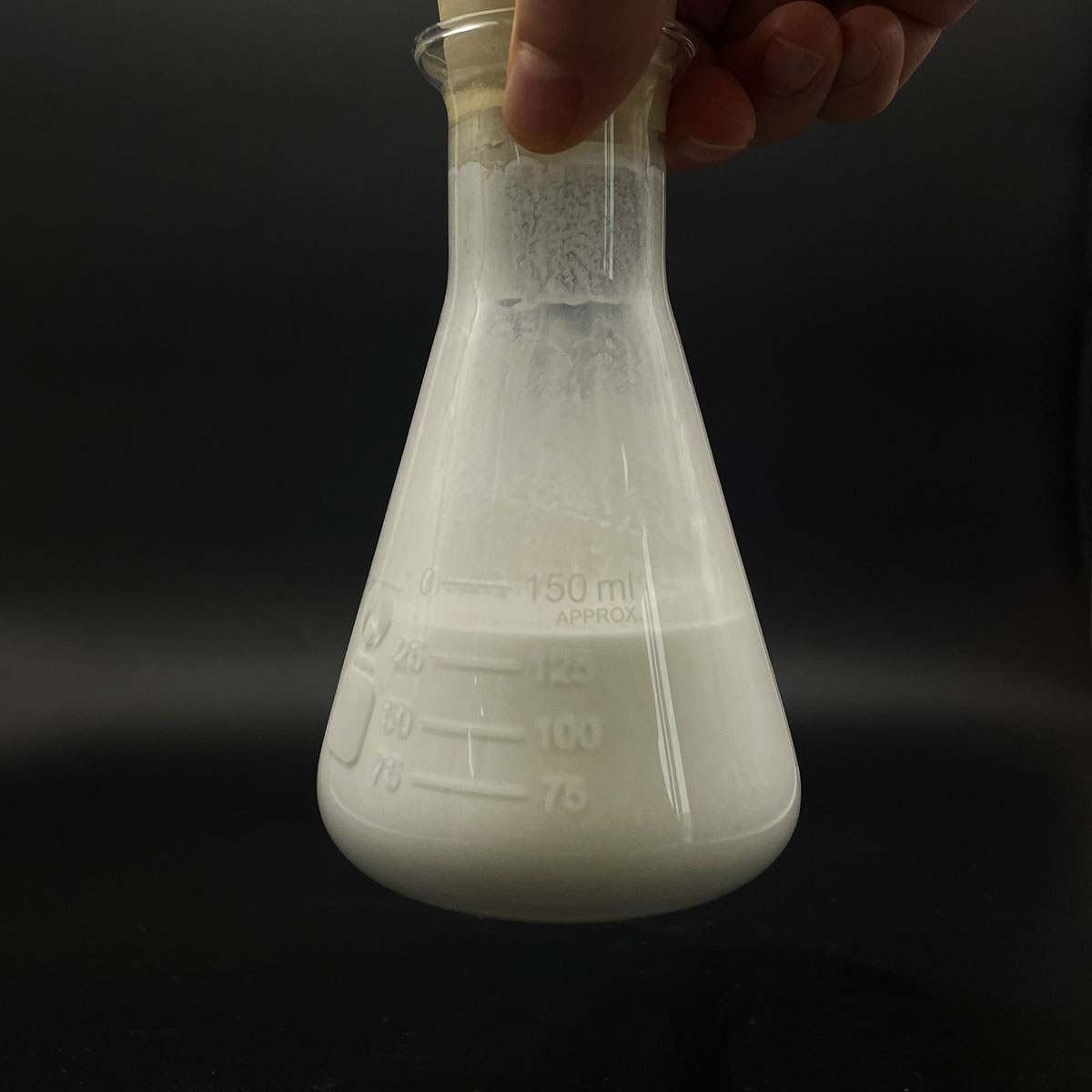

These cationic bitumen emulsifiers are key ingredients for making cationic bitumen emulsion. This emulsion mixes asphalt bitumen with water. The emulsifier makes this mixture possible. It helps tiny droplets of bitumen stay suspended in the water. This creates a stable liquid product. Builders use this emulsion for road construction and maintenance tasks.

There are different types of cationic emulsifiers. Primary emulsifiers form the base emulsion. Auxiliary emulsifiers fine-tune the emulsion properties. The emulsifier’s concentration matters a lot. Too little emulsifier won’t stabilize the emulsion properly. Too much emulsifier can cause problems. It might slow down the breaking process. The breaking process is when the emulsion separates back into bitumen and water on the road surface. The right concentration is crucial for good performance.

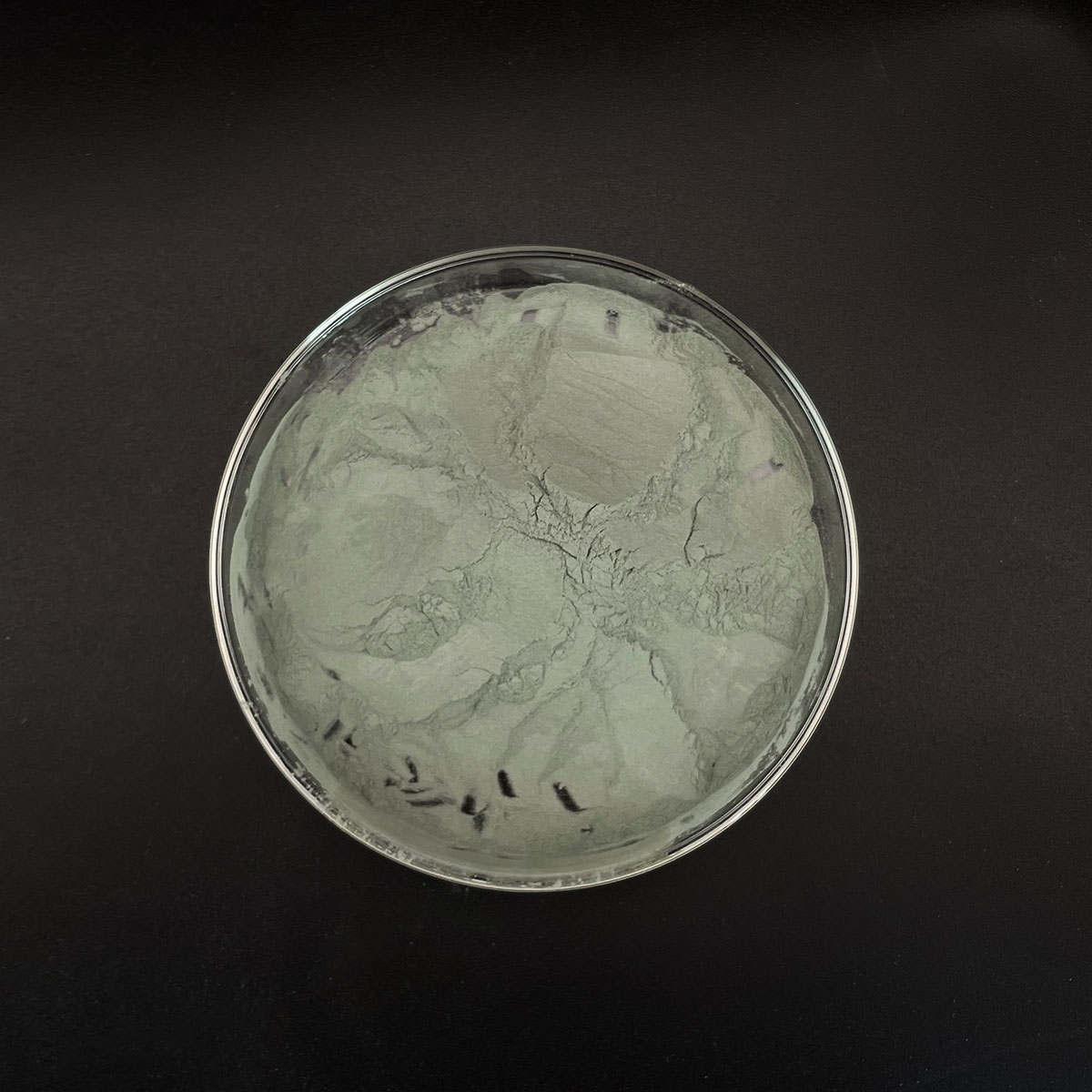

The mixing ratio between emulsifier, bitumen, and water is vital. This ratio directly affects the emulsion’s characteristics. Important properties include viscosity, storage stability, and breaking behavior. The emulsifier must work well with the specific type of bitumen used. Different bitumen grades might need slightly different emulsifier adjustments. The emulsifier also influences how well the emulsion bonds to aggregates like stone chips.

Performance specifications are critical. The emulsifier must produce an emulsion that stores well. It should not separate quickly. The emulsion must break correctly when applied. It should coat the aggregates properly. It must resist premature breaking during mixing or paving. The emulsifier should be easy to handle and add during production. It should be compatible with standard emulsion manufacturing equipment. Builders need reliable performance for consistent results on the job site. These emulsifiers are essential for creating high-quality cationic emulsions used in chip seals, slurry seals, and micro-surfacing.

(Asphalt Mixture Cationic Bitumen Emulsifiers for Cationic Bitumen Emulsion)

Applications of Asphalt Mixture Cationic Bitumen Emulsifiers for Cationic Bitumen Emulsion

Cationic bitumen emulsifiers are important chemicals for making cationic bitumen emulsion. Bitumen is very thick and sticky, especially when cold. Mixing it with water seems impossible. Emulsifiers make this mixing happen. They act like tiny bridges. These emulsifiers have a special structure. One part loves water. The other part loves oil. They surround tiny bitumen droplets in the water. This stops the droplets from sticking together. The result is a smooth, liquid mix. We call this cationic bitumen emulsion.

This liquid emulsion is much easier to handle than hot bitumen. Workers can pump it and spray it easily. This is a big advantage. It allows for cold mix asphalt applications. Cold mix means no need for high heating temperatures. Traditional hot mix asphalt needs very high heat. This uses lots of energy. It also creates fumes and smoke. Cold mix using emulsion avoids these problems. It saves energy. It is safer for workers. It is better for the environment too. You can use cold mix in many weather conditions.

Cationic bitumen emulsion has many uses in road building and repair. One major use is in cold mix asphalt. This mix is made with aggregate and the emulsion. It stays workable longer than hot mix. This is good for patching roads or making roads in remote places. Transporting hot mix far away is difficult. Cold mix solves this problem. Another key use is surface treatments. Chip seal is a common example. Workers spray a layer of emulsion onto the road surface. Then they spread small stones over it. The emulsion holds the stones in place. This seals the road and gives it a new surface. It is a fast and cheap way to fix roads. Tack coats are another application. This is a thin layer of emulsion. It helps new asphalt layers stick to old layers. It creates a strong bond. Emulsion is also used for dust control on gravel roads. It binds the surface and stops dust. Soil stabilization uses emulsion too. It makes weak soil stronger for road bases.

Company Introduction

Welcome to Robocup, a premier global supplier of high-quality surfactants. Our extensive range includes anionic, cationic, nonionic, and amphoteric surfactants, catering to industries such as personal care, textiles, cleaning, and industrial applications. With advanced manufacturing facilities and rigorous quality control, we ensure that our products meet the highest international standards. We pride ourselves on our commitment to innovation, sustainability, and customer satisfaction. Our dedicated team provides tailored solutions to meet your specific needs. Partner with us for reliable, high-performance surfactants that drive your business forward. Explore our offerings and discover the difference today.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Asphalt Mixture Cationic Bitumen Emulsifiers for Cationic Bitumen Emulsion

What are cationic bitumen emulsifiers?

Cationic bitumen emulsifiers are special chemicals. They help mix bitumen with water. Bitumen is thick. Water is thin. The emulsifier makes them combine smoothly. It creates a stable liquid mix. This mix is called cationic bitumen emulsion. It is used in road construction.

Why choose cationic emulsifiers over anionic types?

Cationic emulsifiers work better with common road aggregates. Aggregates are rocks and stones. Many aggregates have a negative charge. Cationic emulsifiers carry a positive charge. Positive and negative charges attract. This attraction helps the emulsion stick to the stones. It improves adhesion. Better adhesion means stronger roads. Anionic types have a negative charge. They might not stick as well to negatively charged stones.

How do these emulsifiers actually work?

The emulsifier molecule has two ends. One end likes oil. It sticks to the bitumen. The other end likes water. It faces the water. This action surrounds the bitumen droplets. It forms a protective layer. This layer stops the droplets from joining together. It keeps the emulsion stable. The charge on the emulsifier helps too. It keeps the droplets apart. They don’t clump up.

What are key performance features?

Good cationic emulsifiers must work well. They should create a stable emulsion quickly. The emulsion must stay stable during storage and transport. It should break at the right time. Breaking means the water separates from the bitumen. This must happen when it contacts the road stones. The emulsifier controls the breaking time. Fast breaking is good for some jobs. Slow breaking is good for others. The emulsifier must be easy to handle and safe.

How should cationic emulsifiers be stored?

Store cationic emulsifiers correctly. Keep them in sealed containers. Keep them away from heat and direct sun. Heat can spoil the product. Store them in a dry, cool place. Check the manufacturer’s instructions. Follow their guidelines. Use the emulsifier before its expiry date. Proper storage ensures it works well.

(Asphalt Mixture Cationic Bitumen Emulsifiers for Cationic Bitumen Emulsion)

REQUEST A QUOTE

RELATED PRODUCTS

Surface Sizing Agent with Cationic Ionicity for Water Proofing Agent

Anionic/ Cationic Surface Sizing Agent Paper Surface Sizing Chemicals in Shandong

Tack Coat Bitumen Emulsion Asphalt Emulsions Cationic Slow Settings Css-1steel Drums Tack Coat Bitumen 60 70

C-404 Emulsifier Used Cationic Quick-Set Emulsions Surry Seal and Microsurfacing

Paper Water Proofing Additive Cationic Surface Sizing Agent