High-Quality Surfactants for Global Markets - Trusted Manufacturer

PRODUCT PARAMETERS

Description

Overview of Nonionic Surfactant

Nonionic surfactants are surface-active agents that do not ionize in aqueous solutions. They are widely used in various industries, including detergents, cosmetics, and pharmaceuticals, due to their excellent solubilizing, emulsifying, and wetting properties. These surfactants are derived from alcohols, acids, or amines and are known for their versatility and compatibility with other surfactants.

Features of Nonionic Surfactant

Non-Ionic Nature: Do not form ions in water, making them less sensitive to hard water and electrolytes.

Versatility: Compatible with both anionic and cationic surfactants, allowing for broad formulation flexibility.

Solubilization: Excellent at solubilizing oils and other hydrophobic substances.

Emulsification: Effective in creating stable emulsions, which is crucial for many cosmetic and pharmaceutical formulations.

Wetting Ability: Enhances the wetting of surfaces, improving cleaning efficiency.

Low Foaming: Generally produce less foam compared to other types of surfactants, which can be advantageous in certain applications like industrial cleaning.

Temperature Stability: Maintain effectiveness over a wide range of temperatures, making them suitable for high-temperature processes.

Environmental Friendliness: Some nonionic surfactants are biodegradable, contributing to more environmentally friendly products.

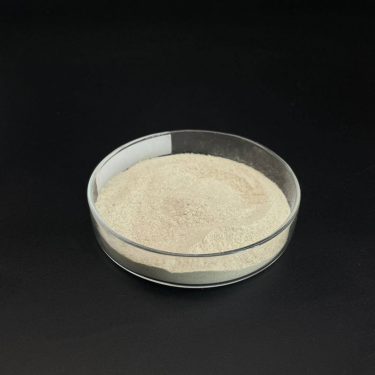

(Factory White Powder Cationic Anionic Nonionic Polymer Flocculant Polyacrylamide)

Specifications of Factory White Powder Cationic Anionic Nonionic Polymer Flocculant Polyacrylamide

This white powder is polyacrylamide. Factories use it a lot. It helps clean water and treat sludge. There are three main types: cationic, anionic, and nonionic. Each type works differently. Cationic polymer has a positive charge. It sticks well to stuff with a negative charge. This makes it good for dirty water with lots of organic matter. It helps pull sludge together. Anionic polymer has a negative charge. It sticks to stuff with a positive charge. It works well in water treatment for minerals. It helps settle particles fast. Nonionic polymer has no charge. It works mainly by sticking particles together physically. It is useful when the water chemistry is tricky. It is gentle but effective. All types come as a fine white powder. This powder dissolves in water easily. You add just a small amount. It works fast. It makes tiny particles clump into big ones. These big clumps sink or float. Then you can remove them easily. This process is called flocculation. The powder is very efficient. It saves money because you need less. It works in many industries. Factories use it for wastewater treatment. Mines use it for separating minerals. Paper mills use it too. It helps make paper stronger. The powder stores well. Keep it dry and cool. It lasts a long time. Handling is simple. Follow basic safety rules. Wear gloves and a mask. Choose the right type for your job. Cationic for organic sludge. Anionic for mineral stuff. Nonionic for sensitive situations. The powder solves many water clarity problems. It makes treatment processes better.

(Factory White Powder Cationic Anionic Nonionic Polymer Flocculant Polyacrylamide)

Applications of Factory White Powder Cationic Anionic Nonionic Polymer Flocculant Polyacrylamide

Factory white powder polyacrylamide flocculant comes in three main types: cationic, anionic, and nonionic. Each type works differently. They help separate solids from liquids in dirty water. These chemicals are used in many industries.

Water treatment plants use them a lot. They help clean drinking water. They make particles clump together. These clumps sink or float. This makes the water clearer. Wastewater plants also rely on them. They remove sludge and other waste. This makes the water safe to release back into rivers. Sludge dewatering needs these flocculants too. They make the sludge thicker. This reduces its volume. It becomes easier and cheaper to handle.

The mining industry uses these flocculants heavily. They process minerals. They separate valuable ore from waste rock. Flocculants help settle the fine particles in tailings ponds. This makes the water clearer. It allows the water to be reused. It also makes the tailings safer to store. Mineral processing uses flocculants for similar settling tasks.

Paper mills use polyacrylamide flocculants. They help retain fine fibers and fillers. This improves paper quality. It reduces waste. These flocculants also help water drain faster from the pulp. This speeds up the papermaking machine. It saves energy.

The oil and gas industry uses these chemicals. They treat the water produced during drilling. They help control the thickness of drilling mud. In oil recovery, flocculants push more oil out of the ground. They improve the flow of water used for flooding.

Company Introduction

Welcome to Robocup, a premier global supplier of high-quality surfactants. Our extensive range includes anionic, cationic, nonionic, and amphoteric surfactants, catering to industries such as personal care, textiles, cleaning, and industrial applications. With advanced manufacturing facilities and rigorous quality control, we ensure that our products meet the highest international standards. We pride ourselves on our commitment to innovation, sustainability, and customer satisfaction. Our dedicated team provides tailored solutions to meet your specific needs. Partner with us for reliable, high-performance surfactants that drive your business forward. Explore our offerings and discover the difference today.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory White Powder Cationic Anionic Nonionic Polymer Flocculant Polyacrylamide

Here are answers to common questions about our factory white powder polymer flocculants, cationic, anionic, and nonionic polyacrylamide. What is polyacrylamide? It is a man-made polymer, a chain-like molecule. We make it as a white powder. It works as a flocculant. Flocculants help tiny particles in water clump together. Bigger clumps settle faster. This makes water clearer. How does polyacrylamide work? The polymer chains grab onto small particles in dirty water. It pulls these particles together. This forms larger groups called flocs. These flocs are heavy. They sink to the bottom quickly. Cleaner water stays on top. What is polyacrylamide used for? Its main job is treating dirty water. Factories use it to clean wastewater before releasing it. Cities use it to treat drinking water. Mines use it to separate solids from water. It helps in sludge dewatering too. This makes sludge thicker and easier to handle. What is the difference between cationic, anionic, and nonionic types? The charge matters. Dirty particles in water can have different charges. Cationic polyacrylamide has a positive charge. It attracts negatively charged particles. Anionic polyacrylamide has a negative charge. It attracts positively charged particles. Nonionic polyacrylamide has no charge. It works well when particles are neutral. Choosing the right type depends on the water you are treating. Is polyacrylamide safe? Handle it carefully. Wear gloves and safety glasses. Avoid breathing in the dust. Follow our instructions. Used correctly, it is safe for water treatment. We provide safety data sheets with all details.

(Factory White Powder Cationic Anionic Nonionic Polymer Flocculant Polyacrylamide)

REQUEST A QUOTE

RELATED PRODUCTS

11041 Nonionic Degreasing Agent Knitting Fabric Auxiliaries Open Width Scouring Agent

Nonionic Trisiloxane Organosilicone Wetting Surfactant

High Quality with Amber Clear Liquid Fn-6810 Nonionic Fluorosurfactant

Nonionic Surfactant Apeo Alkylphenol Ethoxylates High Grade

Lauryl Glucoside APG Good Compatibility Nonionic Surfactants Can Be Used in Various Cleaning Agents