High-Quality Surfactants for Global Markets - Trusted Manufacturer

PRODUCT PARAMETERS

Description

Overview of Cationic Surfactant

Cationic surfactants are surface-active agents with a positively charged hydrophilic head. These surfactants are widely used in various industries, including personal care, textiles, and industrial cleaning. They are known for their antimicrobial properties, making them effective in disinfectants and fabric softeners. Their unique charge allows them to interact strongly with negatively charged surfaces, enhancing their effectiveness in specific applications.

Features of Cationic Surfactant

Positively Charged Head: The cationic nature of these surfactants makes them particularly effective in interacting with negatively charged surfaces.

Antimicrobial Properties: Effective against a wide range of microorganisms, making them ideal for use in disinfectants and sanitizers.

Fabric Softening: Commonly used in fabric softeners due to their ability to provide a soft feel and reduce static cling.

Emulsifying Ability: Can stabilize emulsions, which is useful in cosmetic and personal care products.

Foaming Characteristics: Produces stable foam, beneficial in cleaning products.

Solubility: Generally soluble in water and organic solvents, facilitating their use in various formulations.

Compatibility: Often compatible with other types of surfactants, allowing for versatile formulations.

(Cationic Polyacrylamide CPAM White Powder)

Specifications of Cationic Polyacrylamide CPAM White Powder

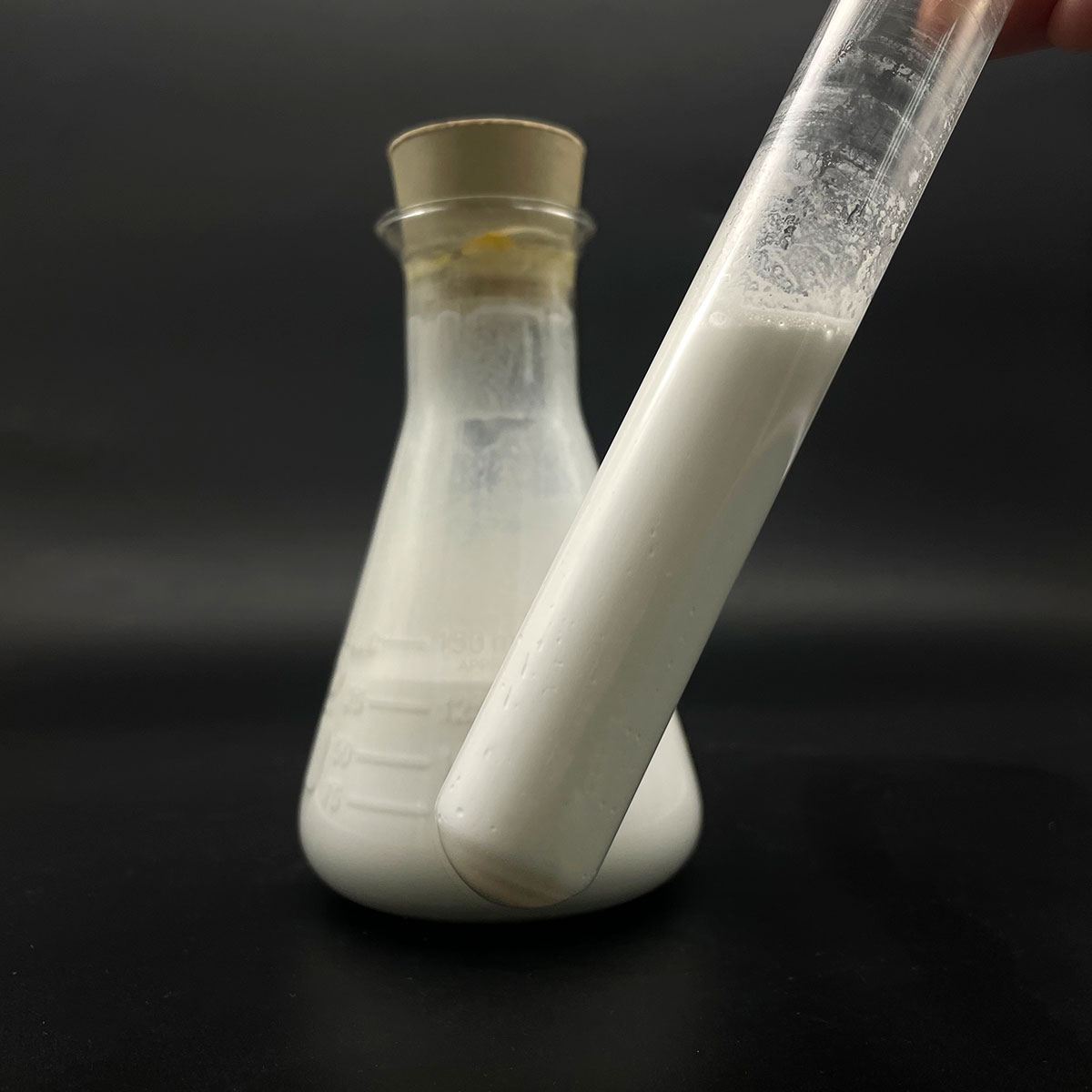

This is Cationic Polyacrylamide, often called CPAM. It comes as a white powder. This powder is a synthetic polymer. It dissolves easily in water. CPAM has a high molecular weight. This means its molecules are very long chains. The powder carries a positive charge. This positive charge is important for how it works.

CPAM is mainly used in water treatment. It works as a flocculant. Flocculants help tiny particles in water stick together. The positive charge on CPAM attracts negatively charged particles. These particles could be dirt, clay, or organic matter. Once attracted, the particles clump together. This forms larger clumps called flocs. These flocs are heavy. They sink to the bottom. Then they are easy to remove. This makes the water clearer.

Many industries use CPAM. Wastewater treatment plants rely on it. It helps clean sewage and industrial wastewater. The mining industry uses CPAM too. It aids in separating minerals from ore slurries. Paper mills use CPAM. It helps retain fine materials during papermaking. This improves paper quality and reduces waste. The oil industry applies CPAM in drilling processes. It helps control fluid viscosity and waste.

The right amount of CPAM is crucial. Too little won’t form good flocs. Too much wastes money and might not work better. Finding the best dose depends on the water. Factors include the type and amount of particles. It also depends on the water’s pH and temperature. Tests are usually needed to find the perfect dose.

CPAM powder needs proper storage. Keep it in a cool, dry place. Moisture can make the powder lumpy. Lumps are hard to dissolve. Store it away from direct sunlight. Sunlight can degrade the polymer over time. Use sealed bags or containers. This prevents moisture from getting in. Stored correctly, CPAM powder lasts a long time.

(Cationic Polyacrylamide CPAM White Powder)

Applications of Cationic Polyacrylamide CPAM White Powder

Cationic Polyacrylamide, called CPAM white powder, is a very useful chemical. It helps in many industries. It is mostly used for water treatment. Wastewater contains dirty particles. These particles often carry a negative charge. CPAM has a positive charge. This positive charge attracts the negative particles. They stick together forming bigger clumps. These clumps are called flocs. Flocs are heavy. They sink to the bottom easily. This makes removing them from the water simpler. Cleaner water results. Municipal water plants use CPAM. Industrial factories use it too. Factories treat their process water before releasing it.

CPAM is also great for sludge dewatering. Factories and plants produce sludge. Sludge contains a lot of water. Removing this water is hard. It costs a lot to dispose of wet sludge. Adding CPAM helps. It makes the sludge particles stick together. Water squeezes out easier. Machines like centrifuges or belt presses work better. Less water means less sludge volume. This saves money on transportation and disposal.

The paper industry relies on CPAM. It acts as a retention aid. Paper is made from fibers and additives in water. Keeping these materials on the paper sheet is important. CPAM helps bind fine particles to the fibers. Less material washes away. This improves paper quality. It also saves materials. Better drainage happens. Water drains faster from the wet paper sheet. Production speed increases. Costs go down.

Mining operations use CPAM white powder too. It helps in mineral processing. Tailings are the waste material. Settling these tailings quickly is necessary. CPAM speeds up the settling. Clear water separates faster. This water can be reused. Coal washing plants need clear water for separation. CPAM helps achieve this clarity. Efficient settling saves time and space.

Company Introduction

Welcome to Robocup, a premier global supplier of high-quality surfactants. Our extensive range includes anionic, cationic, nonionic, and amphoteric surfactants, catering to industries such as personal care, textiles, cleaning, and industrial applications. With advanced manufacturing facilities and rigorous quality control, we ensure that our products meet the highest international standards. We pride ourselves on our commitment to innovation, sustainability, and customer satisfaction. Our dedicated team provides tailored solutions to meet your specific needs. Partner with us for reliable, high-performance surfactants that drive your business forward. Explore our offerings and discover the difference today.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Cationic Polyacrylamide CPAM White Powder

What is Cationic Polyacrylamide (CPAM) White Powder?

Cationic Polyacrylamide White Powder is a synthetic polymer. It is a water-soluble chemical. People use it mainly to treat water and wastewater. It helps remove solids and clarify water. Its white powder form is common for storage and handling.

How does CPAM White Powder work?

CPAM works through a process called flocculation. It carries a positive electrical charge. This charge attracts negatively charged particles in dirty water. These particles include things like clay, silt, and organic matter. The CPAM binds these particles together. It forms larger clumps called flocs. These flocs are heavy. They sink or float, making them easy to remove. Cleaner water is the result.

How do you use CPAM White Powder?

You need to prepare CPAM as a solution before adding it to water. First, dissolve the powder in clean water. Make a stock solution. The usual concentration is 0.1% to 0.5%. Stir gently when dissolving. Avoid vigorous mixing. This prevents breaking the polymer chains. Add this solution slowly to the wastewater. Mix it gently to spread it around. Adjust the dosage based on the water quality. Watch the results. Find the best amount for your specific situation.

How should CPAM White Powder be stored?

Store CPAM powder correctly. Keep it in a cool, dry place. Avoid direct sunlight and moisture. Use sealed containers or bags. This stops the powder from absorbing water. Clumping happens if it gets wet. Clumping makes it harder to dissolve later. Keep it away from heat sources and strong oxidizers. Proper storage keeps the product effective longer.

Is CPAM White Powder safe to handle?

Handle CPAM powder carefully. It is generally safe. But, take basic precautions. Avoid breathing in the dust. Wear a dust mask if needed. Wear gloves to prevent skin contact. Wash your hands after handling. If it gets in your eyes, rinse them with water immediately. Check the Material Safety Data Sheet (MSDS) for specific safety details. Follow the instructions on the label.

(Cationic Polyacrylamide CPAM White Powder)

REQUEST A QUOTE

RELATED PRODUCTS

Cationic Natural Polymer Hydroxypropyl Guar Hydroxypropyltrimonium Chloride

High Ion Charge Cationic Polyacrylamide PAM Polymer for Industrial

Hony Sw Cationic Surfactant for Hair Conditioner High Solid Content

Quaternary Ammonium Salt Cationic Surfactant Polyamine Quaternium-27

SAE Based Cationic Surface Sizing Agent Water Proofing Agent for Paper Making Industry